Lappato abrasive tools are specialized tools that are used in the production of ceramic tiles with a lappato finish. These tools are designed to create a smooth, matte finish on the surface of the tiles by evenly abrading the surface. The specific type of abrasive material used in these tools can vary, but some common abrasives include diamond abrasives, silicon carbide abrasives, and alumina abrasives. These tools are typically used in the final stages of tile production, after the tiles have been fired and glazed. The use of lappato abrasive tools allows manufacturers to create tiles with a sleek, modern finish that is easy to clean and maintain.

Lappato Abrasive used for ceramic tile

Lappato Abrasive

Mesh/ Grit Size: 60 ~ 8000 #.

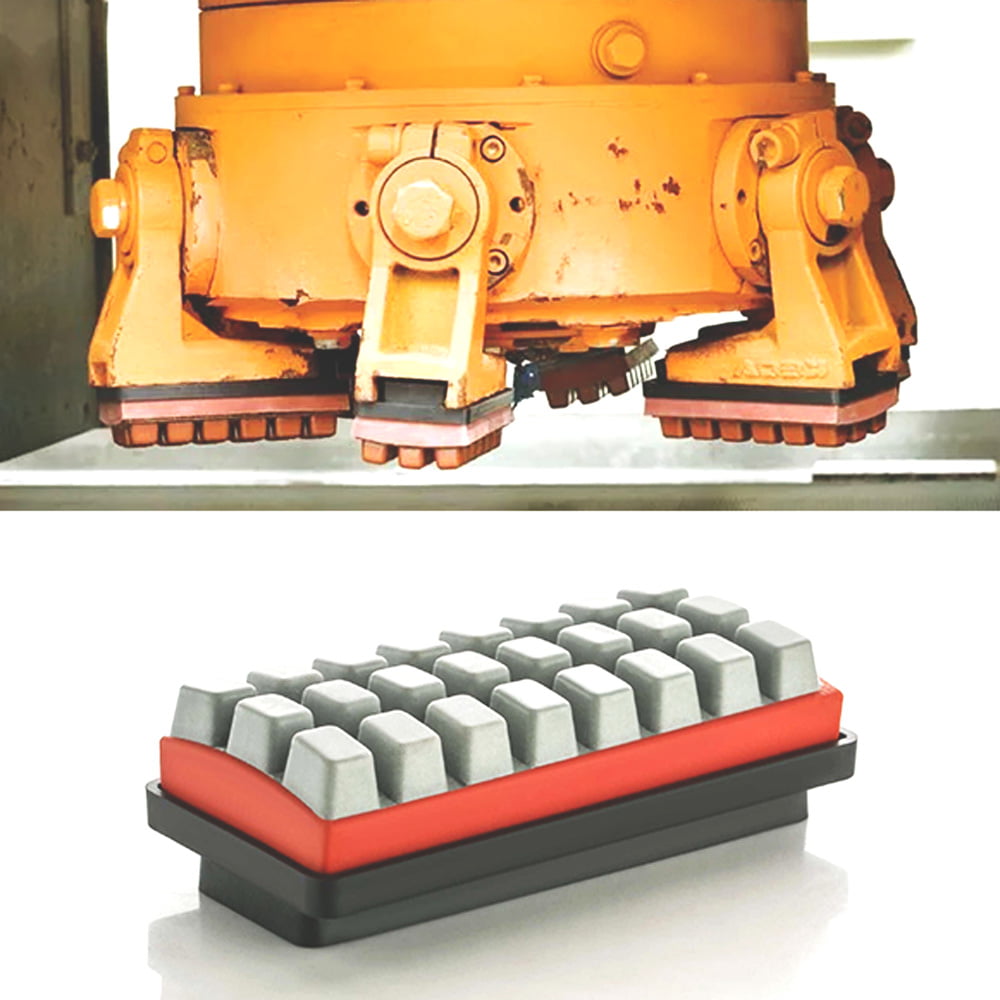

Lappato Abrasive is a diamond grinding tool installed on the polishing machine in the middle of the tile production line to polish the surface of tile or stone.

Diamond Lappato Abrasive is a wide range used for full polishing glazed tiles,semi-polishing glazed tiles, interior wall glazed tiles,stone-like tiles,crystal-effect tiles, rustic tiles, concave, and all kinds of glazed vitrified tiles.

Installed on semi-automatic or automatic ceramic polishing machines.

Lappato Abrasive can be used for full polishing and semi-polishing of tile or stone surfaces. Basair Lappato Abrasive has good temperature control technology, good sharpness, and good durability.

Type Size: 90mm, 140mm, 170mm.

Used For: Finishing Polishing for smooth surface or soft polishing.

Standard: Suitable for any type of Fickert Polishing Machine Head in 90, 130, 140, and 170 mm. sizes.

Color: Yellow, White, Grey, Blue, Or Customized.

Customized Products are Available.

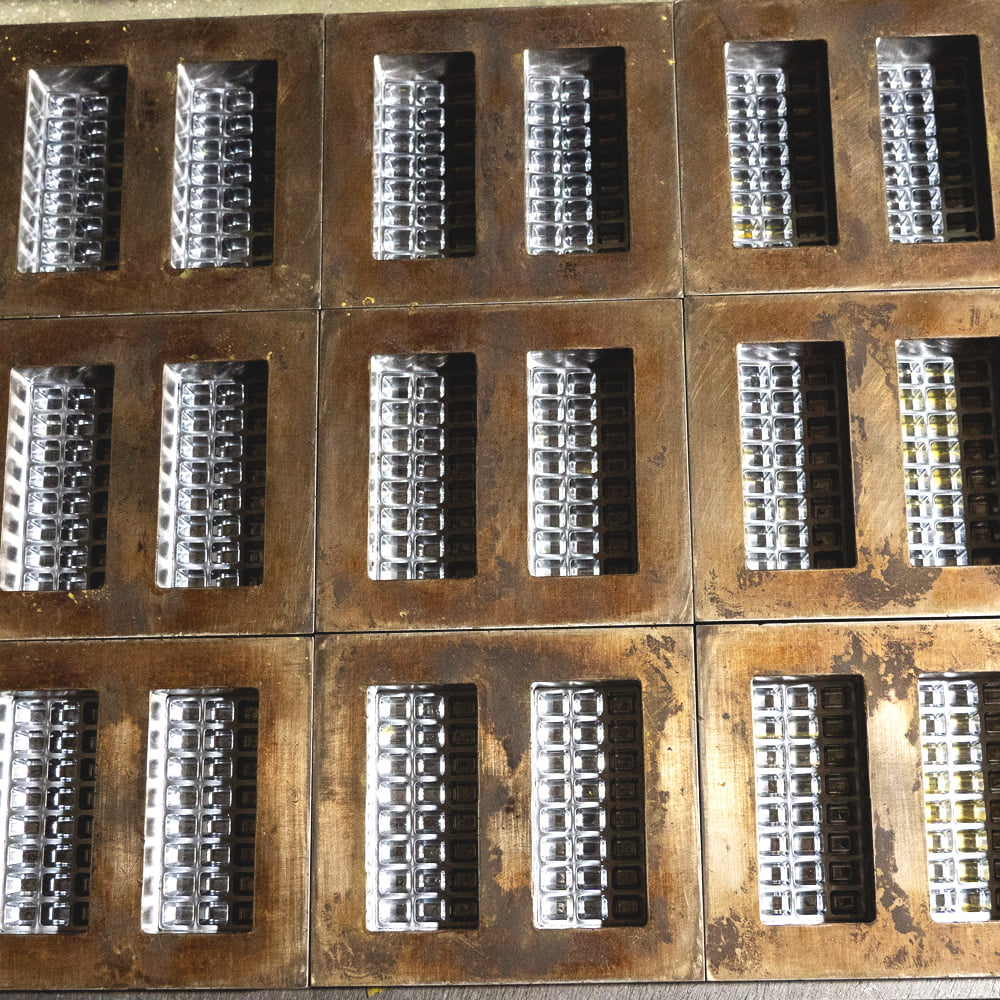

Diamond Lappato AbrasiveLong/Short Teeth

Diamond Lappato AbrasiveBevel Teeth

Diamond Lappato AbrasiveSquare Teeth

Diamond FickertMetal Bond

Diamond Polishing BlockMetal Bond

Diamond Lappato ToolsResin Bons

How to choose lappato abrasive tools?

When choosing lappato abrasive tools for use in the production of ceramic tiles, there are a few key factors to consider. First, it is important to consider the type of abrasive material that is used in the tools. Different abrasive materials will produce different finishes on the tiles, so it is important to choose a material that will achieve the desired result. For example, diamond abrasives are known for their durability and ability to produce a high quality finish, while silicon carbide abrasives are more budget-friendly but may not be as long-lasting. It is also important to consider the type of tool that is used. Different types of lappato abrasive tools, such as pads, discs, and brushes, may produce different finishes on the tiles, so it is important to choose the right tool for the job. Additionally, it is important to consider the size and shape of the tiles that will be finished, as well as the desired level of abrasiveness and the overall production process. Consulting with a specialist or an experienced ceramic tile manufacturer can help to ensure that the right lappato abrasive tools are chosen for the job.

what is the high-quality lappato abrasive?

The specific definition of “high quality” when it comes to lappato abrasives can vary depending on the context and the desired end result. In general, a high-quality lappato abrasive is one that is able to produce a smooth, even finish on the surface of the tiles, without leaving behind any scratches or other imperfections. The abrasive material should be durable and long-lasting, so that it can be used for a large number of tiles without losing its effectiveness. Additionally, a high-quality lappato abrasive should be able to produce a finish that is easy to clean and maintain, without requiring excessive maintenance or special cleaning products. Some common materials that are considered high-quality lappato abrasives include diamond abrasives, silicon carbide abrasives, and alumina abrasives. These materials are known for their durability and ability to produce a high-quality finish on ceramic tiles.

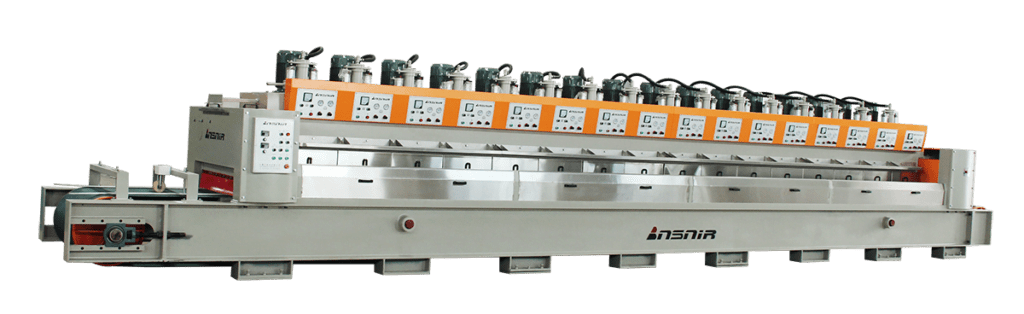

Line Polishing Machine

A line polishing machine is a specialized piece of equipment that is used in the production of ceramic tiles. It is a machine that is designed to polish the surface of the tiles to create a smooth, glossy finish. Line polishing machines typically consist of a series of polishing heads or discs that are mounted on a moving conveyor belt. The tiles are placed on the conveyor belt and pass through the polishing heads, which use abrasive materials and mechanical force to polish the surface of the tiles. Line polishing machines are typically used in the final stages of ceramic tile production, after the tiles have been fired and glazed. They are used to create a smooth, glossy finish on the surface of the tiles, which is desired for certain applications, such as in bathrooms and kitchens. The specific type of abrasive material used in line polishing machines can vary, but some common materials include diamond abrasives, silicon carbide abrasives, and alumina abrasives.