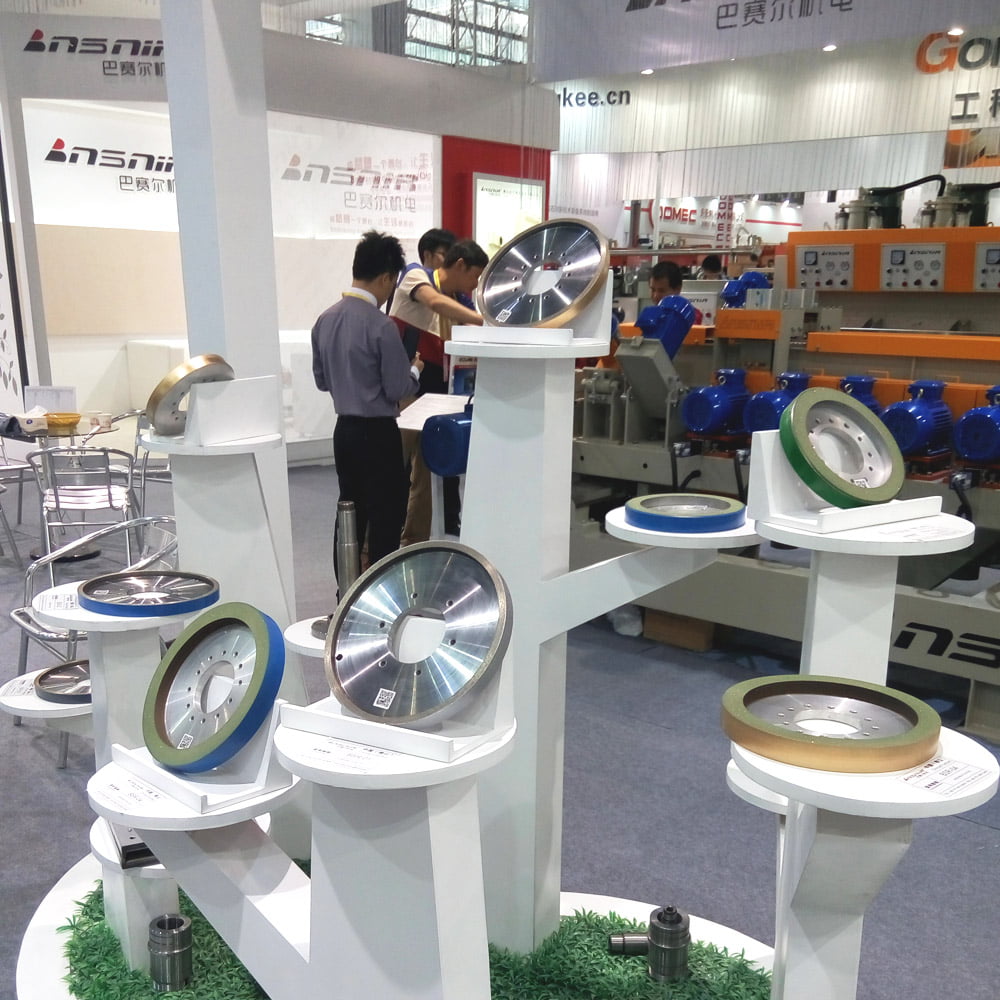

Squaring Wheel

A squaring wheel is a type of abrasive tool that is used in the ceramic tile manufacturing industry. It is typically used to smooth and square the edges of ceramic tiles after they have been cut to size. The diamond abrasive on the surface of the squaring wheel allows it to efficiently grind and shape the edges of the tiles, resulting in a smooth, even finish. This is an important step in the ceramic tile production process, as it ensures that the tiles are uniform in size and have a professional-looking finish.

Dry squaring wheels are characterized by the fact that no water needs to be added during the edging operation. It avoids some tiles with high water absorption rates from absorbing expansion caused by adding water and water stains formed on the surface after drying. And it avoids the quality risk of mildew and discoloration on the surface of tiles caused by excessive moisture during storage and transportation. Because there is no need to use water, the cost of drying equipment and sewage treatment equipment in the production line is saved.

Squaring Wheel used for ceramic tile

Squaring Wheel - Dry

Mesh/ Grit: 60 ~ 300 #.

Squaring Wheel is an abrasive tool used for modifying the edging of ceramic tile on four sides in tile production.

Customer Benefits:

Basair Brand Squaring Wheels can perform stable work at high speed and heavy loads. Reduce downtime and maintenance time in production, and reduce customer use costs.

Products Feature:

Basair brand edging wheels have the characteristics of high grinding force, good stability, and excellent thermal control performance. And the surface of the processed tiles is delicate and smooth.

Applicable Machines:

KEDA, ANCORA, BMR, PEDRINI, KEXINDA, LIBEN, KELID, and other brands of tile squaring machine production lines.

Application Scopes:

Various ceramic tiles, porcelain tiles, glazed tiles, polished tiles, vitrified tiles, crystal tiles, floor tiles, wall tiles, interior tiles, exterior tiles, etc.

Application Sizes:

300×300, 300×600, 600×600, 600×900, 600×1200, 1000×1000, 1200×1200, 750×1500, 900×1800, etc.

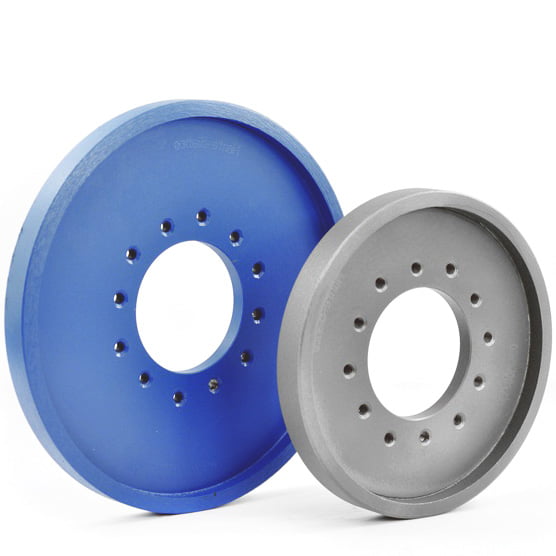

Squaring Wheel used for ceramic tile

Diamond Wheel - Steel Base

Mesh/ Grit: 60 ~ 90 #.

Outer Diameter (mm) | 200/250/300 |

Inner Diameter (mm) | 80/140 |

PCD (mm) | 105/110 |

Cutting Ring – Width (mm) | 8/10 |

Cutting Ring – Height (mm) | 10/12/14 |

Shape of Ring | Toothless |

Customized Products are Available.

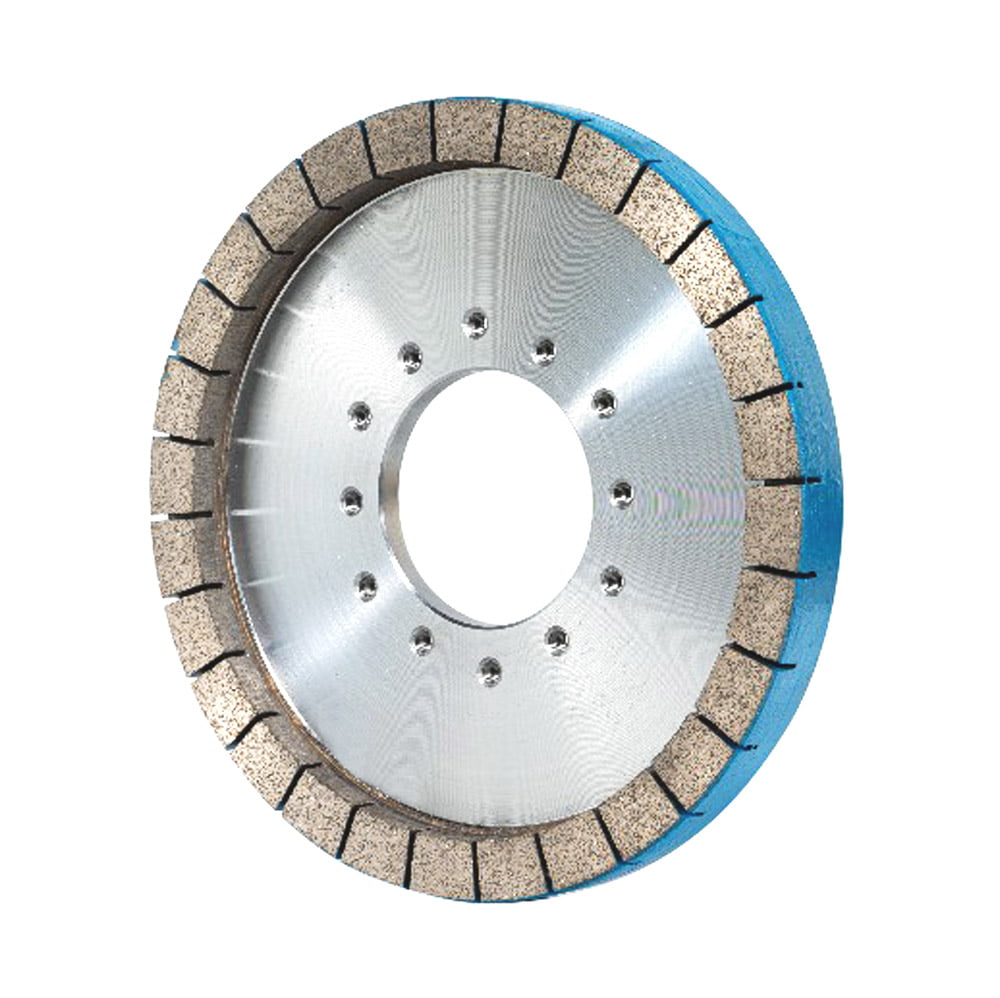

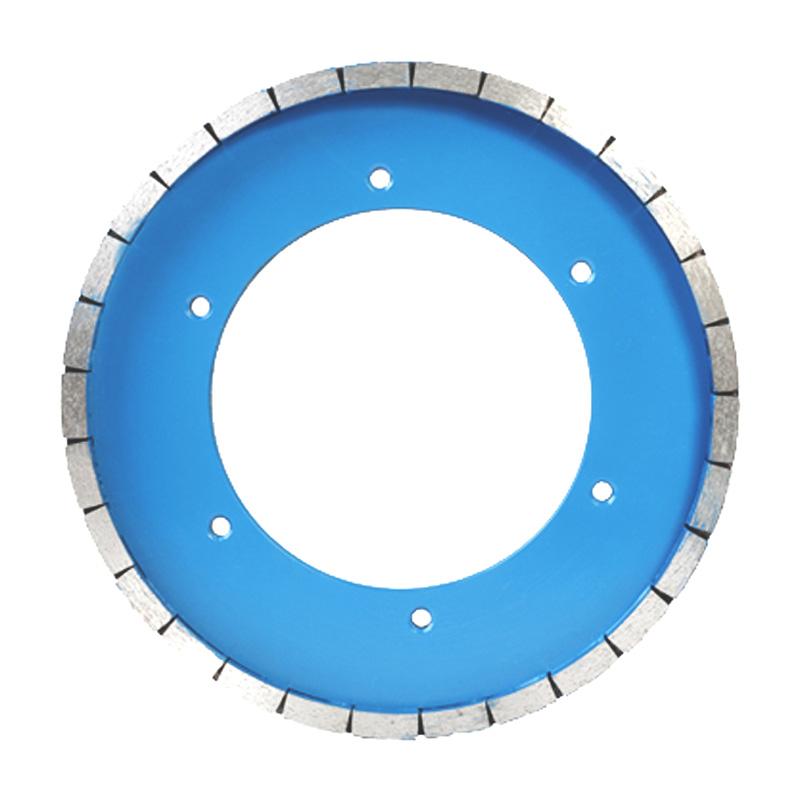

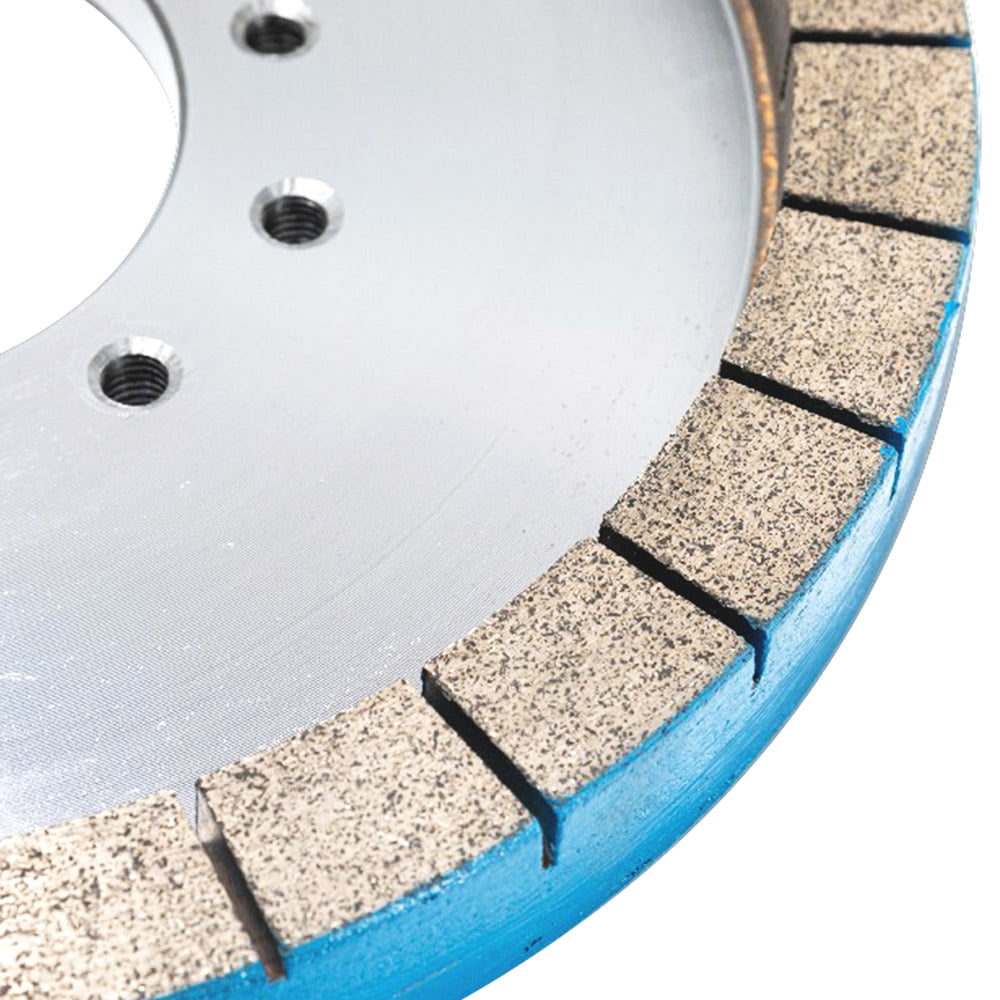

Squaring Wheel used for ceramic tile

Diamond Wheel - Steel Base

Mesh/ Grit: 80 ~ 160 #.

Outer Diameter (mm) | 200/250/300 |

Inner Diameter (mm) | 80/140 |

PCD (mm) | 105/110 |

Cutting Ring – Width (mm) | 20 |

Cutting Ring – Height (mm) | 10/12/14 |

Shape of Ring | Toothed |

Customized Products are Available.

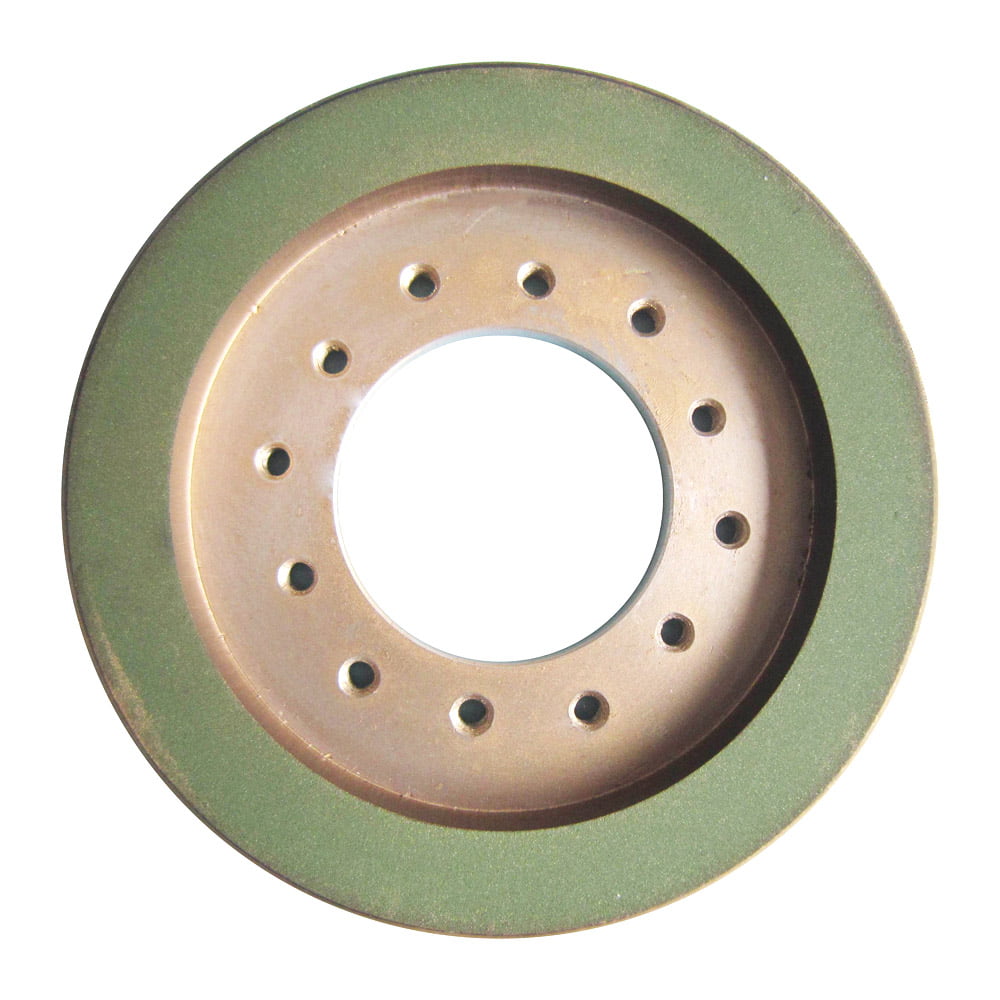

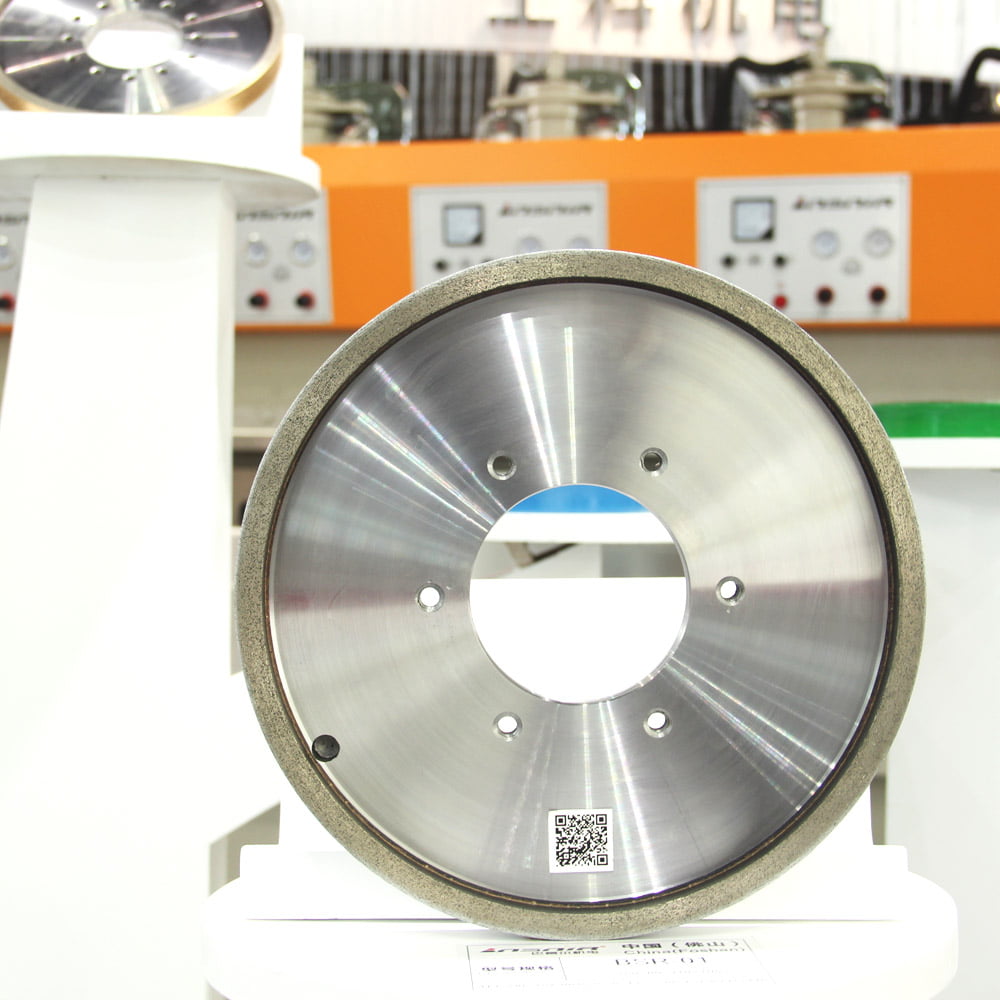

Squaring Wheel used for ceramic tile

Resin Wheel - Aluminum Base

Mesh/ Grit: 80 ~ 160 #.

Outer Diameter (mm) | 200/250 |

Inner Diameter (mm) | 80/140 |

PCD (mm) | 105/110 |

Cutting Ring – Width (mm) | 25 |

Cutting Ring – Height (mm) | 15/20 |

Shape of Ring | Toothless |

Customized Products are Available.

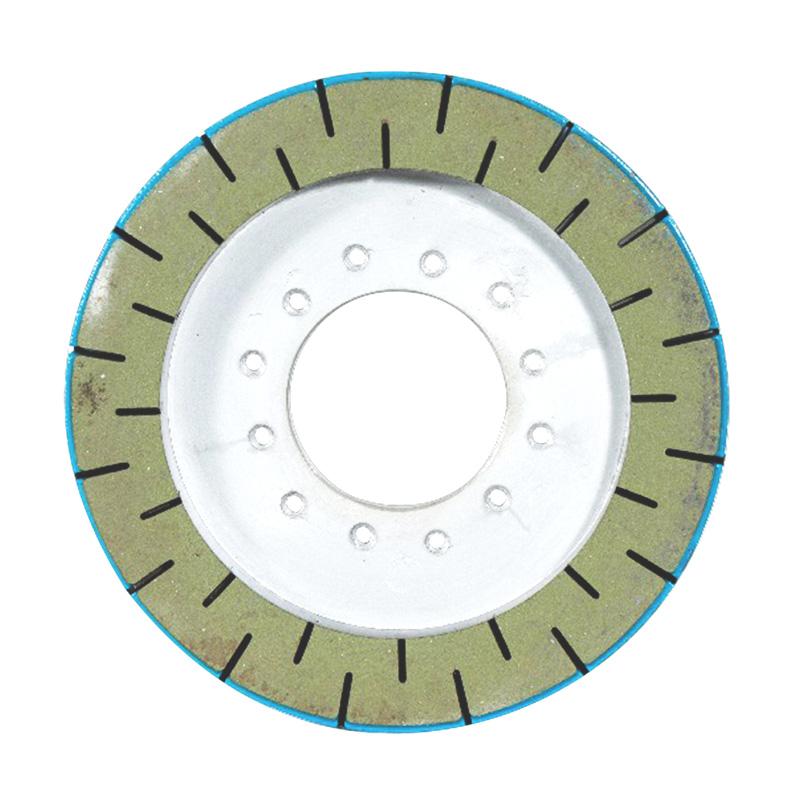

Squaring Wheel used for ceramic tile

Resin Wheel - Aluminum Base

Mesh/ Grit: 120 ~ 300 #.

Outer Diameter (mm) | 200/250 |

Inner Diameter (mm) | 80/140 |

PCD (mm) | 105/110 |

Cutting Ring – Width (mm) | 25 |

Cutting Ring – Height (mm) | 15/20 |

Shape of Ring | Toothed |

Customized Products are Available.

Basair Brand Water Squaring Wheel is a kind of edging tool installed in the squaring machine line to production for ceramic tile production with water conditions. The difference between it and the dry squaring wheel is that because of the addition of water, the contact surface between the edging wheel and the tile is cooled. The squaring wheel can grind tiles at a higher speed without worrying about quality problems such as glaze chipping and black edges.

The water squaring machine line has many advantages and is generally used in conjunction with a polishing machine. But the disadvantage is that drying machine to production tile is required, and it can only handle tiles with low water absorption rate.

Squaring Wheel used for ceramic tile

Squaring Wheel - Water

Mesh/ Grit: 120 ~ 300 #.

Squaring Wheel is an abrasive tool used for modifying the edging of ceramic tile on four sides in tile production.

Customer Benefits:

Basair Brand Squaring Wheels can perform stable work at high speed and heavy loads. Reduce downtime and maintenance time in production, and reduce customer use costs.

Products Feature:

Basair brand edging wheels have the characteristics of high grinding force, good stability, and excellent thermal control performance. And the surface of the processed tiles is delicate and smooth.

Applicable Machines:

KEDA, ANCORA, BMR, PEDRINI, KEXINDA, LIBEN, KELID, and other brands of tile squaring machine production lines.

Application Scopes:

Various ceramic tiles, porcelain tiles, glazed tiles, polished tiles, vitrified tiles, crystal tiles, floor tiles, wall tiles, interior tiles, exterior tiles, etc.

Application Sizes:

300×300, 300×600, 600×600, 600×900, 600×1200, 1000×1000, 1200×1200, 750×1500, 900×1800, etc.

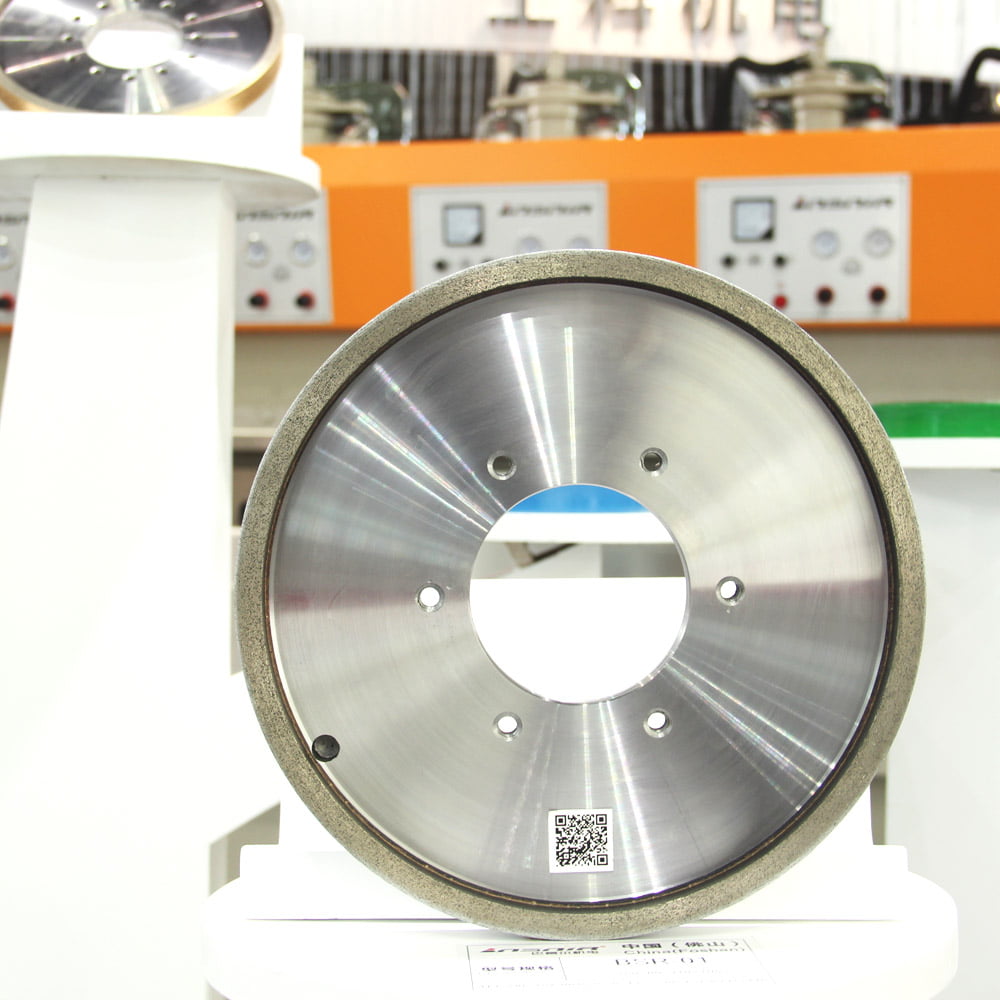

Squaring Wheel used for ceramic tile

Diamond Wheel - Steel Base

Mesh/ Grit: 120 ~ 300 #.

Outer Diameter (mm) | 200/250 |

Inner Diameter (mm) | 80/140 |

PCD (mm) | 165 |

Cutting Ring – Width (mm) | 10/25 |

Cutting Ring – Height (mm) | 12/15/20 |

Shape of Ring | Toothed |

Customized Products are Available.

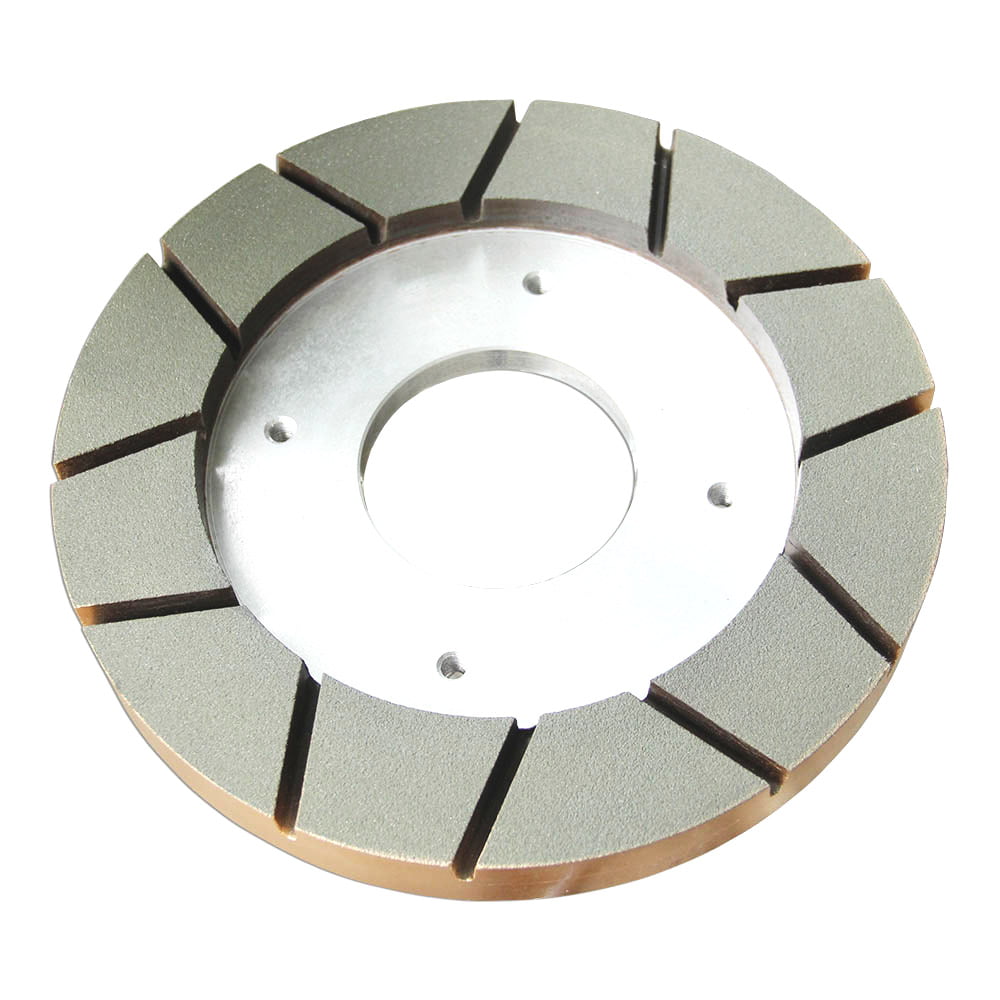

Squaring Wheel used for ceramic tile

Resin Wheel - Aluminum Base

Mesh/ Grit: 120 ~ 300 #.

Outer Diameter (mm) | 200/250/300 |

Inner Diameter (mm) | 80/140 |

PCD (mm) | 165 |

Cutting Ring – Width (mm) | 25/30 |

Cutting Ring – Height (mm) | 12/15 |

Shape of Ring | Toothless |

Customized Products are Available.

chamfering Wheel used for ceramic tile

Resin Chamfering Wheel

Mesh/ Grit: 120 ~ 300 #.

The chamfering wheel is suitable for the backstage of ceramic tile production, fine chamfering, smooth, sharp, flat, and long service life.

The silicon carbide chamfering wheel using resin bond is suitable for the fine chamfering of ceramic tiles and has the characteristics of smooth and sharp chamfering and long continuous working time.

The diamond chamfering wheel using resin bond is used to chamfer the tiles after trimming. Its function is to ensure the safety of transportation and use and avoid potential risks caused by chipping or excessively sharp tile edges.

Chamfering Wheel used for ceramic tile

Silicon Carbide Chamfering Wheel

Mesh/ Grit: 140 ~ 360 #.

Outer Diameter (mm) | 125/130 |

Cutting Ring – Width (mm) | 25/40 |

Cutting Ring – Height (mm) | 12/15/18/20 |

Customized Products are Available.

Chamfering Wheel used for ceramic tile

Diamond Chamfering Wheel

Mesh/ Grit: 140 ~ 360 #.

Outer Diameter (mm) | 125/150/200/250 |

Cutting Ring – Width (mm) | 6/10/25 |

Cutting Ring – Height (mm) | 12 |

Customized Products are Available.

how many types of squaring wheels?

There are several different types of squaring wheels available on the market. The most common types include straight squaring wheels, beveled squaring wheels, and multi-purpose squaring wheels.

Straight squaring wheels are designed for use on straight edges and are typically used to smooth and square the edges of ceramic tiles. Beveled squaring wheels, on the other hand, are designed for use on angled edges and are typically used to create beveled edges on ceramic tiles.

Multi-purpose squaring wheels, as the name suggests, are designed for use on both straight and angled edges. These squaring wheels are versatile and can be used on a variety of different tile shapes and sizes.

In addition to these three main types of squaring wheels, there are also other specialized squaring wheels available, such as squaring wheels for use on porcelain tiles and squaring wheels for use on mosaic tiles. The type of squaring wheel you choose will depend on the specific needs of your ceramic tile manufacturing process.

How to choose the right type of squaring wheel?

When choosing a squaring wheel for ceramic tile production, there are a few factors to consider. First, you should consider the type of ceramic tiles you are working with. Different types of tiles may require different types of squaring wheels. For example, if you are working with porcelain tiles, you will need a squaring wheel that is specifically designed for use with porcelain.

Next, you should consider the size of the tiles you are working with. Squaring wheels come in different sizes, so it is important to choose a size that is appropriate for your needs. For example, if you are working with large tiles, you will need a larger squaring wheel.

Additionally, you should consider the quality of the squaring wheel. High-quality squaring wheels are made with durable materials and are designed to provide a smooth, even finish. This is important because a poor-quality squaring wheel can result in uneven edges on the tiles, which can affect their overall appearance and quality.

Finally, you should also consider the cost of the squaring wheel. While it is important to invest in a high-quality squaring wheel, you also want to make sure that it fits within your budget. There are many different squaring wheels available on the market, so it is important to shop around and compare prices to find the best value for your money.

How to avoid edge chipping, glaze chipping and black edge in tile processing?

There are several steps you can take to avoid edge chipping, glaze chipping, and black edge in tile processing.

One way to prevent edge chipping is to use a high-quality squaring wheel that is specifically designed for use with ceramic tiles. A good squaring wheel will help to smooth and square the edges of the tiles, reducing the risk of chipping. Additionally, it is important to use the squaring wheel properly and follow the manufacturer’s instructions to ensure that it is used correctly and safely.

To prevent glaze chipping, it is important to ensure that the glaze on the tiles is applied evenly and in the right amount. Over-glazing or uneven glazing can cause the glaze to chip or crack, leading to glaze chipping. Additionally, it is important to avoid using sharp or abrasive tools on the glazed surface of the tiles, as this can also cause the glaze to chip.

To avoid black edge in tile processing, it is important to properly clean and maintain your equipment. Black edge can be caused by a buildup of dirt and debris on the squaring wheel and other equipment. Regularly cleaning and maintaining your equipment can help to prevent this from happening. Additionally, it is important to use the correct type of squaring wheel for the tiles you are working with. Using the wrong type of squaring wheel can lead to black edge and other issues.

Squaring Machine Line

A squaring machine line is a specialized piece of equipment that is used in the production of ceramic tiles. It is a machine that is designed to cut the tiles to a specific size and shape, and to produce straight, square edges. They are used to cut the tiles to the desired size and shape, and to ensure that they have straight, square edges. Squaring machine lines typically consist of a conveyor belt or other moving surface that carries the tiles through the machine. The tiles are held in place by a series of clamps or other holding devices and are cut to size by a series of Squaring Wheels. The specific type of cutting tools used in squaring machine lines can vary, but they are typically made from high-quality, durable materials, such as diamond or carbide, to ensure that they can produce clean accurate cuts.